The penicillin war: India’s journey from selfsufficiency

to dependence on China

Synopsis

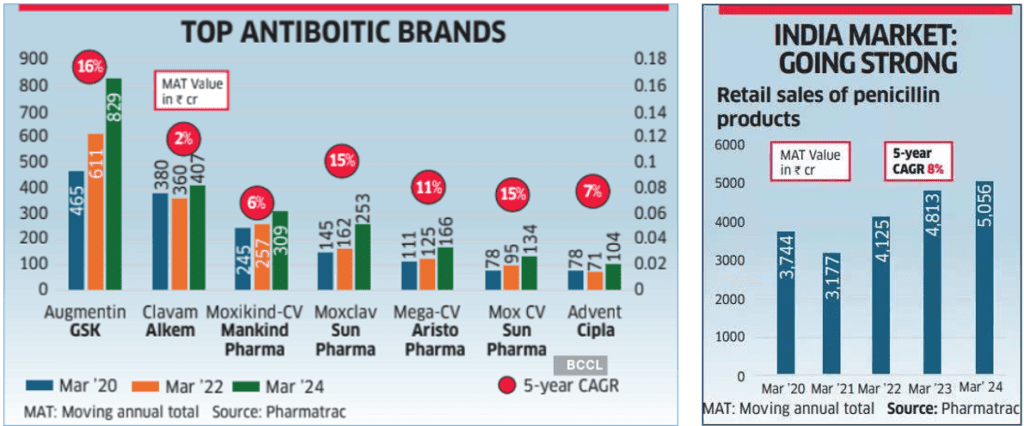

After India lost its dominance in making penicillin, a drought of three decades is coming to an end. The drug – which forms the base for a raft of extremely potent antibiotics – is part of the govt’s aggressive push for self-sufficiency in critical areas. Will the plan to claw back to the glorious past work?

The year was 1928. After a weekend break, when Scottish physician and microbiologist Sir Alexander Fleming returned to his lab in St. Mary’s Hospital in London, a big surprise was waiting. He found a blue-green mould growing in one of the petri dishes. Intrigued, his mind went probing on the cause of contamination. Soon Fleming realised he had stumbled upon a discovery that would be hailed as one of the world’s biggest medical breakthroughs. By sheer serendipity, Fleming found the mould had destroyed colonies of staphylococcal bacteria around it.

Penicillin — the nemesis for the deadliest bacterial infections — was born. Gruelling work followed. In 1945, Fleming along with his legendary team of researchers Ernst Chain and Sir Howard Florey were awarded the Nobel Prize in physiology and medicine. As World War II unleashed deaths and miseries, a miracle weapon armed doctors against life-threatening bacterial infections. Until then, minor cuts or bruises carried risks of deaths. Penicillin saved lives of soldiers grievously injured during the war.

An article in Science Museum describes the quick build-up to make the drug. It says such was its demand that scientists used every conceivable object — from bed pans to bathtubs — to store volumes of broth for the fermentation process. Gallons of mould broth were needed to get a fingernail of penicillin, says the article. With time, as scientists developed better methods of extraction, it spawned dozens of producers across Europe and the US.

THE OWNERSHIP GAME

Nearly a century from its discovery, the relevance of the wonder drug has only grown in combating the scourge of bacterial infections. Even the newest generations of anti-infective treatments like carbapenems are derived from penicillin. The miracle continues to charm scientists. But Fleming’s humble penicillin did not take too long to be at the centre of a heated global trade war.

“Those with dominance (in producing the drug) held key to supplies and command prices at will. If supplies were stopped a global health crisis was inevitable,” says a veteran industry source. For its part, in the sixties, India was self-sufficient in making penicillin but over the next three decades, the game changed and it became entirely dependent on China. But the lessons were learnt from the Covid-19 pandemic. With over-dependence on supplies of basic materials from the Chinese, supplies of essential medicines posed a serious challenge.

“China can win this war without firing a single bullet,” said an executive. With that threat looming, India is making efforts to claw back to some of its past glory. Last month, Hyderabad-based Aurobindo Pharma commissioned a

manufacturing plant to produce penicillin with a capacity of 15,000 metric tonnes per annum at a cost of around Rs 2,400 crore. The government’s production-linked incentive (PLI) scheme for drug makers, offering tax and duty relaxation for five years, is a shot in the arm.

THE INDIA STORY

But how did India lose its grip and see a dramatic decline from self-sufficiency to complete dependence on the Chinese. “First, large European drug makers like UK’s Glaxo (now GSK) and Biotika of Slovekia held sway,” the executive quoted above says.

In the fifties and sixties, leading drug companies of that time such as Barodabased Alembic, Sarabhai Chemicals, Hindustan Antibiotics and India Drugs and Pharmaceuticals took the first step in making penicillin, seeing the big opportunity. They invested heavily in large fermentation facilities, a maze of processes that usually took 2,000 steps at that time.

“India destroyed the Europeans (in making penicillin a low-cost product), and then the Chinese killed the Indians the same way,” he says, having witnessed those days up close. Penicillin gave a badge of recognition. Alembic had developed its own technology from a high-yielding strain from Japan’s Meiji Seiko Kaisha. Others like SPIC, Torrent Pharma and Standard Pharma of Kolkata had followed.

The Indian government-backed unit IDPL received the technology knowhow from Russia. In his quaint office in Goregaon’s bustling Udyog Nagar in Mumbai, Dinesh Shantilal Patel, executive chairman of Themis Medicare, unfolds like an encyclopaedia on the subject. He reminisces the days when India had established its clout in penicillin.

“Around seventies or eighties, the government reserved the production of penicillin, gentamycin, streptomycin, oxytetracycline only for public sector undertakings.”

“Even until the nineties, pharmaceutical companies (which were into making finished products or medicines) were keen on securing indigenous sources of raw materials. But then the big Chinese invasion killed the market in no time. With Indian formulators sourcing their raw materials from Chinese, the API producers were choked to death,” he says.

ENTER THE DRAGON

According to one estimate, amoxycillin, a hugely used penicillin derivative, was dumped by the Chinese at $9-10 per kg against set international rate of $25-30 per kg. The story was the same for many other products. That tilted the scale against Indian drug makers.

“Neither the formulations industry was helping, nor the government was listening. It was a dead end,” Patel says. “When the government noticed that prices of imported raw material from China were significantly lower and the commensurate prices of medicines high, they played the DPCO (Drug Price Control Order) card. The Indian producers of raw material incurred losses and had to finally shut operations,” he adds.

DPCO is part of the government’s policy to monitor and regulate prices of hundreds of essential drugs, adjusted periodically according to the cost of production. Patel says the imposition of DPCO was the start of the end of the Indian API sector during the nineties.

“The government did not see the coming tsunami. There was no proactive approach in extending protection against the indiscriminate Chinese dumping,” he adds. But It didn’t take long to see the Chinese game plan. With Indian drug makers entirely moving to Chinese intermediates and raw materials, they jacked up the prices by as much as 4x their lowest rates.

In an exhaustive study in 2021, Reji K Joseph and Ramaa Arun Kumar from the Institute for Studies in Industrial Development traced the growth and the decline of the Indian API industry. In an extract, they say excess production in China made it dump Pen-G (penicillin) in India at costs below 40% of the actual cost of production. As a result, the price of Pen-G crashed to $6/BU as compared to $24/BU between 1985 and 2003.

“There was also a major reduction in import tariffs. The import duty of organic chemicals including KSMs (key starting material), DIs (drug intermediates) and APIs was reduced from 120% in 1990-91 to 7.5% in 2007-08. By 2012, the production capacity of Pen-G in India had declined to 2500-3500 MMU (mega-million units) and that of China increased to 160,000 MMU,” the study notes.

“In 2003, Pen-G was removed from the negative list. After the removal of restrictions on import of Pen-G, the domestic producers gradually withdrew from production – HAL (2003), JK Pharma and Torrent (2007), and Alembic (2011),” it adds.

Critics say while the government finally seems to be aware of the risks from China’s imports, there remain quite a few concerns on the self-sufficiency plans. “What is the guarantee that the Chinese will not crash the prices again?” says an analyst. Already the prices of many raw materials from China are available at half of the peak pandemic period. “That also is the reason for reluctance to take up the PLI scheme,” he says.

There is complete dependence on China for many other products like vitamins. India’s penicillin crisis is far from over.